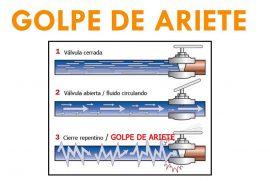

Hydraulic shock ( water hammer; fluid hammer) is a pressure surge or wave caused when a fluid, usually a liquid but sometimes also a gas, in motion is forced to stop or change direction suddenly; a momentum change. This phenomenon commonly occurs when a valve closes suddenly at an end of a pipeline system, and a pressure wave propagates in the pipe.

This pressure wave can cause major problems, from noise and vibration to pipe collapse. It is possible to reduce the effects of the water hammer pulses with surge tanks , and other features.

When a pipe is suddenly closed at the outlet (downstream), the mass of water before the closure is still moving, thereby building up high pressure and a resulting shock wave. In domestic plumbing this is experienced as a loud banging resembling a hammering noise. Water hammer can cause pipelines to break if the pressure is high enough. Air traps or stand pipes (open at the top) are sometimes added as dampers to water systems to absorb the potentially damaging forces caused by the moving water.

In hydroeletric generating stations , the water traveling along the tunnel or pipeline may be prevented from entering a turbine by closing a valve. For example, if there is 14 km (8.7 mi) of tunnel of 7.7 m (25 ft) diameter full of water travelling at 3.75 m/s (8.4 mph),that represents approximately 8,000 megajoules (2,200 kWh) of kinetic energy that must be arrested. This arresting is frequently achieved by a surge shaft open at the top, into which the water flows. As the water rises up the shaft its kinetic energy is converted into potential energy, which causes the water in the tunnel to decelerate. At some hydroelectric power (HEP) stations, such as the Saxon Falls Hydro what looks like a is actually one of these devices, known in these cases as a surge drum .

At home, a water hammer may occur when a toilet or dishwasher shuts off water flow. The result may be heard as a loud bang, repetitive banging (as the shock wave travels back and forth in the plumbing system), or as some shuddering.

On the other hand, when an upstream valve in a pipe closes, water downstream of the valve attempts to continue flowing creating a vacuum that may cause the pipe to collapse or implode. This problem can be particularly acute if the pipe is on a downhill slope. To prevent this, air and vacuum relief valves or air vents are installed just downstream of the valve to allow air to enter the line to prevent this vacuum from occurring.

Other causes of water hammer are pump failure and check valve slam (due to sudden deceleration, a check valve may slam shut rapidly, depending on the dynamic characteristic of the check valve and the mass of the water between a check valve and tank). To alleviate this situation, it is recommended to install non-slam check valves as they do not rely on gravity or fluid flow for their closure. For vertical pipes, other suggestions include installing new piping that can be designed to include air chambers to alleviate the possible shockwave of water due to excess water flow.

Português

Português Español

Español